|

|

|

Business News | April 2008 Business News | April 2008

Aerospace Industry Migrating to Mexico in Greater Numbers

Chris Hawley - The Arizona Republic Chris Hawley - The Arizona Republic

go to original

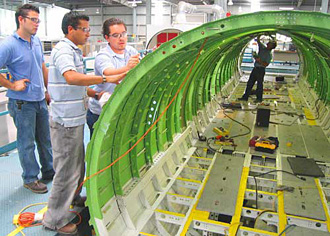

| | A trainer from Canada (second from left) helps Mexican workers assemble the fuselage of a business jet at a Bombardier factory in Querétaro, Mexico, last week. (Chris Hawley/The Arizona Republic | | |

Querétaro, Mexico - Chances are much of your car was built in Mexico. Increasingly, the planes you fly on are, too.

Aerospace companies are streaming to Mexico, drawn by lower wages, enthusiastic government promotion, a new safety agreement with the United States and an increasingly sophisticated workforce.

In a new plant in the central Mexican city of Querétaro, workers who make $3.50 an hour are building rudders and bundles of wiring for airliners. Across town, engineers at General Electric's research center are designing jet engines. In a nearby industrial park, workers are overhauling landing gear at a gleaming new plant.

"Every day, we are seeing more and more activity of this kind in Mexico," said José Javier Roch, head of aviation for Mexico's General Directorate of Civil Aeronautics.

Mexico's aerospace-related exports have more than tripled since 2004, from $146.2 million to $683.2 million last year, and exports are accelerating quickly as manufacturers move into big-ticket items like tails and fuselages. One aircraft maker, Canada's Bombardier Inc., says it hopes to eventually assemble complete jets in Mexico.

Companies say that, because of a booming market for aircraft worldwide, the move to Mexico has not resulted in major layoffs in the United States. But American unions are afraid it might if aviation takes a downturn.

"This is a technological base, an important industrial base for our country, and we're just giving it up," said Ron Eldridge, aerospace coordinator for the International Association of Machinists and Aerospace Workers.

Industry officials liken the trend to the 1980s, when U.S. companies moved from making auto parts in Mexico to assembling entire vehicles there. Now, Mexico exports $42 billion in cars and auto parts every year.

"Mexico's vision is to do the same thing they did with the auto industry," said Real Gervais, head of Bombardier's operations in Mexico. "There's a lot of potential."

Made in Mexico

In a cavernous factory that opened in February at the Querétaro airport, tail sections for Bombardier's Global Express business jet jut up from construction platforms like the fins of giant sharks.Workers in blue polo shirts bustle around the sleek aluminum bodies, drilling holes and placing rivets.

This work used to be done in Toronto. But Bombardier, which makes everything from CRJ regional jetliners to Learjets, has been trying to cut costs while making room for new models in its U.S. and Canadian factories.

Since Bombardier opened its first factory in a rented building in Querétaro in 2006, workers here have taken over production of wire harnesses from plants in Wichita, Kan., rudders from Japan and fuselages from Northern Ireland.

Aircraft makers following Bombardier's lead include:

• Aernnova, a Spanish firm that makes wings, tails and other sections for Boeing, Airbus, Embraer and others. It is building an $84 million plant in Querétaro.

• Cessna Aircraft Co. and Hawker Beechcraft Corp., both makers of business jets, which have both moved subassembly work from their Wichita plants to new factories in the northern city of Chihuahua since 2006.

• MD Helicopters, based in Mesa, which began making fuselages near Monterrey in 2006.

• Goodrich Corp., which s building a 350,000-square-foot factory in Mexicali to make engine nacelles for the Boeing 787 Dreamliner. The Charlotte, N.C., company makes aircraft interiors and engine parts in Arizona.

Lower wages are a big reason behind the moves.

At Bombardier, new assembly workers earn 6,000 pesos a month, or about $560, according to plant manager Michael McAdoo. That's about $3.50 an hour. Engineers can earn $925 to $1,390 a month, according to a Bombardier job ad. That's $5.80 to $8.70 an hour.

The lower costs have translated into a 30 percent savings on parts made here, even after the added transportation costs, Gervais said.

Not everything has gone smoothly, however. At an aviation conference in Querétaro last week, industry officials complained about Mexican government bureaucracy and problems getting parts and equipment through customs. Training Bombardier's Mexican workers took longer than expected because there were no veterans to help show employees the ropes once they got on the factory floor, Gervais said.

"We underestimated the tribal knowledge of the 50 or 75 years of experience that we had in our other sites," he said.

To better train workers, the Mexican government plans to start construction of a national aeronautical university in Querétaro in August.

Brain work

It's not just aerospace manufacturing moving south of the border. Foreign firms are snapping up Mexican engineers and mechanics, as well.

Honeywell Aerospace, a Phoenix-based electronics maker and major Valley employer, opened a $40 million testing center in Mexicali in 2006.

General Electric will add 600 engineers to the 1,000 it already employs at its Querétaro design center, the U.S. Commercial Service said last month. The center designs jet engines and turbines for electrical generators.

Mexico also is becoming a center for maintenance as airlines look for cheaper places to have their planes fixed.

At a new overhaul plant in Querétaro, huge metal struts from a US Airways A320 lay on a table like dinosaur bones waiting to be cleaned, cataloged and inspected.

The SAFRAN Group of France moved the plant from a site near Dulles Airport in Virginia in October, saying it needed to cut costs and was having trouble recruiting U.S. workers. About 160 U.S. workers lost their jobs.

"It's just a shame," said David Athey, a former senior engineer at the Virginia plant. "Very few of those people, maybe 15 percent, went back into aviation. Some people are selling cars, some are plumbers. . . . Whether they're scrubbing bowling balls or working at the dental-hygienist place, everybody has moved on."

At least one U.S. airline, Delta, is already sending entire planes to Mexico for maintenance work. In 2006, it signed a deal handing heavy maintenance of 120 of its planes over to Aeromexico, an airline.

The Mexican government is hoping exports will grow even faster in the wake of a new Bilateral Aviation Safety Agreement signed with the United States in September.

The pact allows Mexican officials to certify new aircraft parts instead of shipping them to the United States for inspection.

"It's a great logistical advantage," Roch said. "It's going to be a detonator for the industry."

Reach the reporter at chris.hawley(at)arizonarepublic.com. |

| |

|